Re-construction of lime kilns

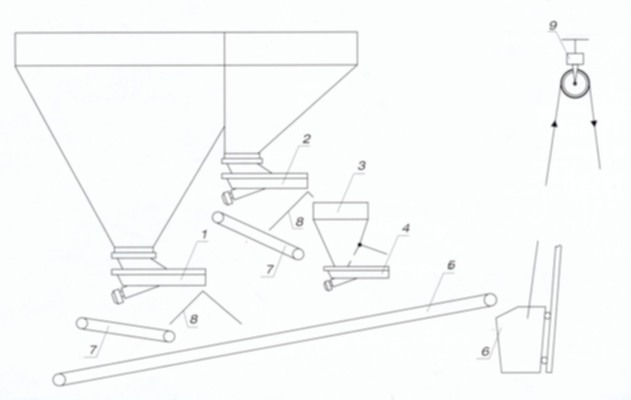

We deliver following technical modifications of a lime kiln to increase effectiveness:

- sorting and weighing of lime stone and coke

- mixing of lime stone and coke before filling in lime kiln

- patent divider with rolling reservoir

- stationary dividing equipment of the filling

- process control

- cooling and purification of carbonation gas

After modification we guarantee CO2 content in carbonation gas over 35 %, its temperature 100 °C and coke consumption max. 7.5 % of lime stone, the temperature of out-putting lime from the kiln max. 50 °C.

The part of realisation is full package of works incl. training of operators and adjusting of kiln behaviour according to laboratory analyses.

Legend to the picture: 1 – dosing device of lime stone with a separator, 2 - dosing device of coke with a separator, 3 – tensiometric balances, 4 – coke dosing device to a transporter, 5 – dosing transporter of filling to skip lift, 6 – skip lift, 7 – transporter of undersizes, 8 – guide plate, 9 – tensiometric balances of skip lift

© VUC Praha, a.s.